| Contents

Home

General

Info

Ordering

Info

Contact us

Cartridge

Lists

Patent &

Miscellaneous

US Rim Fire

US Center Fire

Pistol

US Center Fire US Rifle

Metric

British

Shotgun Shells

Pictures

Posters

Links to Other Sites

Cartridge Collectors Organizations:

IAA

ECRA

SAAACA

Auctions:

Auction

Arms

E-Bay

Ward's Collectibles

Sold USA

Books:

Armory

Publications

WCF Publications

Other Collectr's Sites:

Curtis Steinhauer

|

Home of the

Old Ammo Guy's Virtual Cartridge Trading Table

Picture

Page

May 2004

Happiness is a dirty old shipping

crate...

I have decided to devote the entire picture page for the month of May to

this Union Metallic Cartridge Company shipping crate that was found in Western

Virginia, and the boxes of cartridges that were with it. The crate is constructed

of 3/4"+ planed pine boards, held together with square cut nails. On Christmas

Eve in 1873, as attested to by the date stamped into the wood on both ends,

it was packed at UMC's Bridgeport ammunition works with fifty boxes of .50-70

Springfield cartridges, destined for the Army depot in Washington, D.C..

These were probably part of two million .50 caliber cartridges that the

government contracted with UMC to produce in late 1873.

At that time,

the government arsenals were focused on production of the new .45-70 cartridge,

as the Model 1873 Springfield had just been selected as the standard for

Army use in May of 1873. Once the crate was packed and the top secured in

place, it was painted a dark red, then stenciling and the date stamps

were applied to both ends, and it was ready to be shipped. Upon arrival in

Washington, it was probably packed away and forgotten for a while. Some time

later, the top was painted gray, and addressed in black stenciled lettering At that time,

the government arsenals were focused on production of the new .45-70 cartridge,

as the Model 1873 Springfield had just been selected as the standard for

Army use in May of 1873. Once the crate was packed and the top secured in

place, it was painted a dark red, then stenciling and the date stamps

were applied to both ends, and it was ready to be shipped. Upon arrival in

Washington, it was probably packed away and forgotten for a while. Some time

later, the top was painted gray, and addressed in black stenciled lettering

for shipment

to the Adjutant of the Virginia State Militia, in Richmond. Typically, the

guns and ammunition issued to the states were, in turn, distributed to

the various county militias. These were often stored in the county court

houses where, more often than not, they were never needed. This certainly

seems to be the case for at least a portion of the boxes that were in the

crate, as the ten unopened boxes that came with it are in excellent

condition. The fact that the original top is still with the crate would support

the likelihood that it was still screwed in place when found by the previous

owner. One opened box was also found with the crate, revealing for shipment

to the Adjutant of the Virginia State Militia, in Richmond. Typically, the

guns and ammunition issued to the states were, in turn, distributed to

the various county militias. These were often stored in the county court

houses where, more often than not, they were never needed. This certainly

seems to be the case for at least a portion of the boxes that were in the

crate, as the ten unopened boxes that came with it are in excellent

condition. The fact that the original top is still with the crate would support

the likelihood that it was still screwed in place when found by the previous

owner. One opened box was also found with the crate, revealing

the cartridges

also to be in excellent condition. They are the Berdan primed, unheadstamped

case style with the raised ring head typical of early UMC cartridge production.

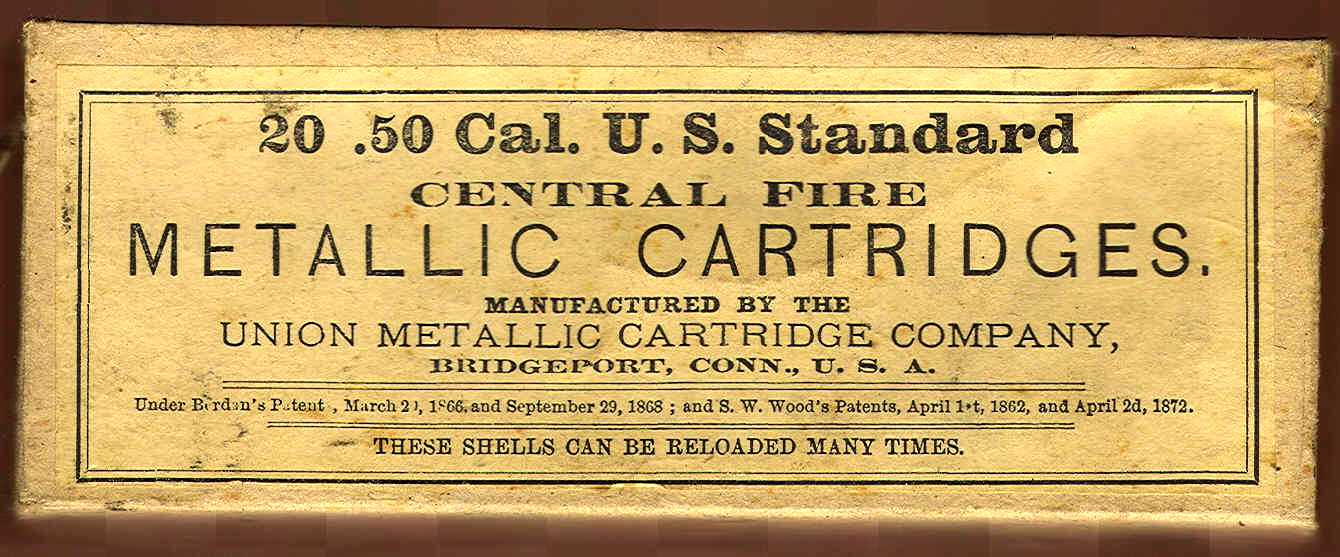

The box labels are rather plain, lacking the 'dog's head' UMC logo that was

standard on the company's ammunition intended for commercial sale during

the 1870s and 1880s. Four patent dates are printed on the labels; these include

Hiram Berdan's patents of March 20, 1866, for the external primer cap and

fixed anvil in

the the cartridges

also to be in excellent condition. They are the Berdan primed, unheadstamped

case style with the raised ring head typical of early UMC cartridge production.

The box labels are rather plain, lacking the 'dog's head' UMC logo that was

standard on the company's ammunition intended for commercial sale during

the 1870s and 1880s. Four patent dates are printed on the labels; these include

Hiram Berdan's patents of March 20, 1866, for the external primer cap and

fixed anvil in

the head of

the shell, and September 29, 1868, for a cup fitted inside the case

to strengthen the head. The other two are S. W. Wood's patents of April 1,

1862 and April 2, 1872, both of which I believe applied to the processes

for forming drawn brass cartridge cases. The boxes themselves are

constructed of four separate pieces of cardboard, consisting of two pieces

to form the body of the box and two end pieces, all held in place by a pasted-on

buff colored paper wrapper, with a pull string head of

the shell, and September 29, 1868, for a cup fitted inside the case

to strengthen the head. The other two are S. W. Wood's patents of April 1,

1862 and April 2, 1872, both of which I believe applied to the processes

for forming drawn brass cartridge cases. The boxes themselves are

constructed of four separate pieces of cardboard, consisting of two pieces

to form the body of the box and two end pieces, all held in place by a pasted-on

buff colored paper wrapper, with a pull string

for opening

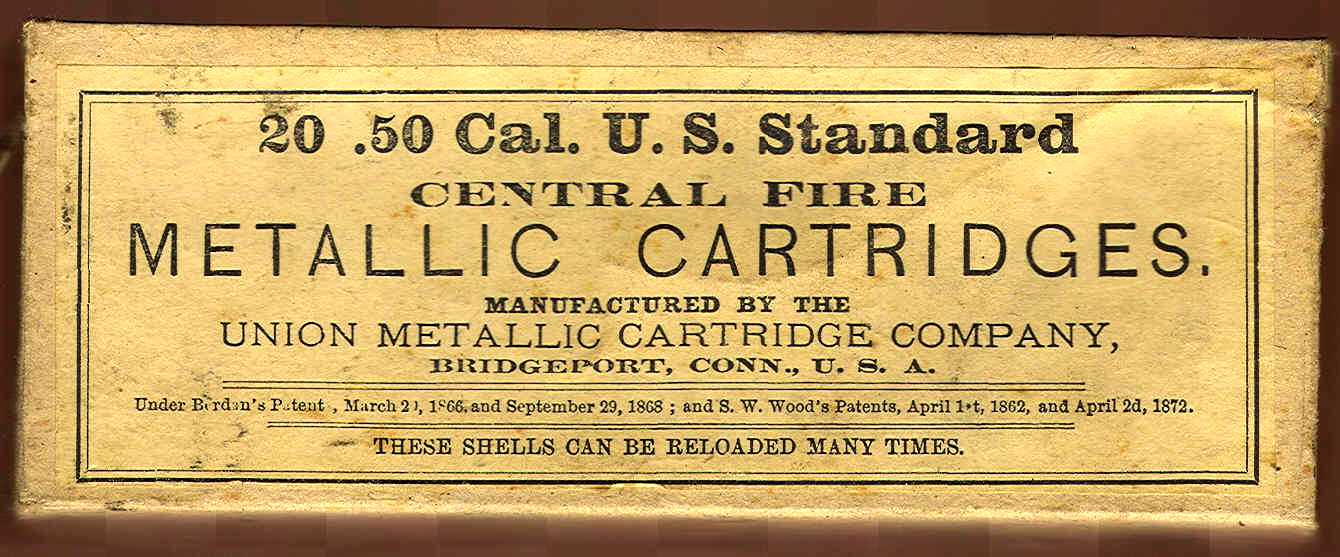

the box. When viewed from the end, as in this last picture, the top

and bottom do not form 90 degree angles to the front and back, but instead

are canted slightly. As a result, when the cartridges are placed in the box,

the bullet tips resting against the angled bottom cause the rims of the front

row of cartridges to be positioned slightly above the back row, allowing

for easier removal of the cartridges from the box. The pull string can

be seen to the upper right in the picture. Pulling this string tears the

paper wrapper across the end of the box, then across the back and the other

end. The top can then be opened and 'hinged' on the untorn wrapper along

the front top edge of the box to expose the cartridges. for opening

the box. When viewed from the end, as in this last picture, the top

and bottom do not form 90 degree angles to the front and back, but instead

are canted slightly. As a result, when the cartridges are placed in the box,

the bullet tips resting against the angled bottom cause the rims of the front

row of cartridges to be positioned slightly above the back row, allowing

for easier removal of the cartridges from the box. The pull string can

be seen to the upper right in the picture. Pulling this string tears the

paper wrapper across the end of the box, then across the back and the other

end. The top can then be opened and 'hinged' on the untorn wrapper along

the front top edge of the box to expose the cartridges.

One lazy weekend shortly after getting the crate my curiosity got the best

of me, and I set out to determine how the boxes would have to be packed in

the crate in order to fit all fifty that were originally shipped. This entailed

making up facsimile boxes which closely matched the dimensions of the originals.

At this point, two of the original boxes had found another home, so

I found myself

up to my elbows in cardboard, paper and glue making the forty two replacements

need to fill the crate. Once these were completed, I found after just a little

trial and error that I could only fit all fifty boxes in by placing them

as shown in the picture, on their ends in four rows of eleven each, with

the last six turned sideways into the remaining space. Its a fairly compact

package, leaving little room for the boxes to shift around. So, how did my

facsimile boxes turn out? Not bad if I say so myself. They are not such close

copies as to be confused with the originals, but certainly good enough to

meet my needs. After I found myself

up to my elbows in cardboard, paper and glue making the forty two replacements

need to fill the crate. Once these were completed, I found after just a little

trial and error that I could only fit all fifty boxes in by placing them

as shown in the picture, on their ends in four rows of eleven each, with

the last six turned sideways into the remaining space. Its a fairly compact

package, leaving little room for the boxes to shift around. So, how did my

facsimile boxes turn out? Not bad if I say so myself. They are not such close

copies as to be confused with the originals, but certainly good enough to

meet my needs. After

making forty

two of them, I'm not only a fairly accomplished box maker, but I also have

a better appreciation for how tedious the work must have been for the UMC

factory workers who made the company's cartridge boxes six long days a week. making forty

two of them, I'm not only a fairly accomplished box maker, but I also have

a better appreciation for how tedious the work must have been for the UMC

factory workers who made the company's cartridge boxes six long days a week.

|

At that time,

the government arsenals were focused on production of the new .45-70 cartridge,

as the Model 1873 Springfield had just been selected as the standard for

Army use in May of 1873. Once the crate was packed and the top secured in

place, it was painted a dark red, then stenciling and the date stamps

were applied to both ends, and it was ready to be shipped. Upon arrival in

Washington, it was probably packed away and forgotten for a while. Some time

later, the top was painted gray, and addressed in black stenciled lettering

At that time,

the government arsenals were focused on production of the new .45-70 cartridge,

as the Model 1873 Springfield had just been selected as the standard for

Army use in May of 1873. Once the crate was packed and the top secured in

place, it was painted a dark red, then stenciling and the date stamps

were applied to both ends, and it was ready to be shipped. Upon arrival in

Washington, it was probably packed away and forgotten for a while. Some time

later, the top was painted gray, and addressed in black stenciled lettering

for shipment

to the Adjutant of the Virginia State Militia, in Richmond. Typically, the

guns and ammunition issued to the states were, in turn, distributed to

the various county militias. These were often stored in the county court

houses where, more often than not, they were never needed. This certainly

seems to be the case for at least a portion of the boxes that were in the

crate, as the ten unopened boxes that came with it are in excellent

condition. The fact that the original top is still with the crate would support

the likelihood that it was still screwed in place when found by the previous

owner. One opened box was also found with the crate, revealing

for shipment

to the Adjutant of the Virginia State Militia, in Richmond. Typically, the

guns and ammunition issued to the states were, in turn, distributed to

the various county militias. These were often stored in the county court

houses where, more often than not, they were never needed. This certainly

seems to be the case for at least a portion of the boxes that were in the

crate, as the ten unopened boxes that came with it are in excellent

condition. The fact that the original top is still with the crate would support

the likelihood that it was still screwed in place when found by the previous

owner. One opened box was also found with the crate, revealing

the cartridges

also to be in excellent condition. They are the Berdan primed, unheadstamped

case style with the raised ring head typical of early UMC cartridge production.

The box labels are rather plain, lacking the 'dog's head' UMC logo that was

standard on the company's ammunition intended for commercial sale during

the 1870s and 1880s. Four patent dates are printed on the labels; these include

Hiram Berdan's patents of March 20, 1866, for the external primer cap and

fixed anvil in

the

the cartridges

also to be in excellent condition. They are the Berdan primed, unheadstamped

case style with the raised ring head typical of early UMC cartridge production.

The box labels are rather plain, lacking the 'dog's head' UMC logo that was

standard on the company's ammunition intended for commercial sale during

the 1870s and 1880s. Four patent dates are printed on the labels; these include

Hiram Berdan's patents of March 20, 1866, for the external primer cap and

fixed anvil in

the head of

the shell, and September 29, 1868, for a cup fitted inside the case

to strengthen the head. The other two are S. W. Wood's patents of April 1,

1862 and April 2, 1872, both of which I believe applied to the processes

for forming drawn brass cartridge cases. The boxes themselves are

constructed of four separate pieces of cardboard, consisting of two pieces

to form the body of the box and two end pieces, all held in place by a pasted-on

buff colored paper wrapper, with a pull string

head of

the shell, and September 29, 1868, for a cup fitted inside the case

to strengthen the head. The other two are S. W. Wood's patents of April 1,

1862 and April 2, 1872, both of which I believe applied to the processes

for forming drawn brass cartridge cases. The boxes themselves are

constructed of four separate pieces of cardboard, consisting of two pieces

to form the body of the box and two end pieces, all held in place by a pasted-on

buff colored paper wrapper, with a pull string

for opening

the box. When viewed from the end, as in this last picture, the top

and bottom do not form 90 degree angles to the front and back, but instead

are canted slightly. As a result, when the cartridges are placed in the box,

the bullet tips resting against the angled bottom cause the rims of the front

row of cartridges to be positioned slightly above the back row, allowing

for easier removal of the cartridges from the box. The pull string can

be seen to the upper right in the picture. Pulling this string tears the

paper wrapper across the end of the box, then across the back and the other

end. The top can then be opened and 'hinged' on the untorn wrapper along

the front top edge of the box to expose the cartridges.

for opening

the box. When viewed from the end, as in this last picture, the top

and bottom do not form 90 degree angles to the front and back, but instead

are canted slightly. As a result, when the cartridges are placed in the box,

the bullet tips resting against the angled bottom cause the rims of the front

row of cartridges to be positioned slightly above the back row, allowing

for easier removal of the cartridges from the box. The pull string can

be seen to the upper right in the picture. Pulling this string tears the

paper wrapper across the end of the box, then across the back and the other

end. The top can then be opened and 'hinged' on the untorn wrapper along

the front top edge of the box to expose the cartridges.

I found myself

up to my elbows in cardboard, paper and glue making the forty two replacements

need to fill the crate. Once these were completed, I found after just a little

trial and error that I could only fit all fifty boxes in by placing them

as shown in the picture, on their ends in four rows of eleven each, with

the last six turned sideways into the remaining space. Its a fairly compact

package, leaving little room for the boxes to shift around. So, how did my

facsimile boxes turn out? Not bad if I say so myself. They are not such close

copies as to be confused with the originals, but certainly good enough to

meet my needs. After

I found myself

up to my elbows in cardboard, paper and glue making the forty two replacements

need to fill the crate. Once these were completed, I found after just a little

trial and error that I could only fit all fifty boxes in by placing them

as shown in the picture, on their ends in four rows of eleven each, with

the last six turned sideways into the remaining space. Its a fairly compact

package, leaving little room for the boxes to shift around. So, how did my

facsimile boxes turn out? Not bad if I say so myself. They are not such close

copies as to be confused with the originals, but certainly good enough to

meet my needs. After

making forty

two of them, I'm not only a fairly accomplished box maker, but I also have

a better appreciation for how tedious the work must have been for the UMC

factory workers who made the company's cartridge boxes six long days a week.

making forty

two of them, I'm not only a fairly accomplished box maker, but I also have

a better appreciation for how tedious the work must have been for the UMC

factory workers who made the company's cartridge boxes six long days a week.