| Contents

Home

General

Info

Ordering

Info

Contact us

Cartridge

Lists

Patent & Miscellaneous

Rim Fire

Center Fire Pistol

Center Fire Rifle

Metric Rimfire,

Pistol&Rifle

British Pistol and Rifle

Shotgun Shells

Posters

This Month's Picture Page

Index to

Picture Pages

Prior Picture Pages:

*

September 2003

*

October 2003

*

November 2003

*

December 2003

*

January 2004

*

February 2004

*

March 2004

*

April 2004

*

May 2004

*

June 2004

*

July 2004

*

August 2004

*

September 2004

*

October 2004

*

November 2004

*

December

2004

*

January 2005

*

February

2005

*

March

2005

*

April

2005

*

May 2005

*June 2005

*July 2005

*August 2005

*September

2005

Links to Other Sites

Cartridge Collectors Organizations:

IAA

ECRA

SAAACA

Auctions:

Auction

Arms

E-Bay

Ward's Collectibles

Sold USA

Books:

Armory

Publications

WCF Publications

Other Collector's Sites:

Curtis Steinhauer

|

Home of the Old Ammo Guy's Virtual

Cartridge Trading Table

Picture

Page

October

2005

A Frankford Arsenal field reloading

set.......

Here's a seldom encountered item, a complete reloading set for the .45

caliber cartridges that were being used by the US Army at the time it was

fabricated at the Frankford Arsenal in the late 1880s. These tool sets were

first produced on an experimental basis in conjunction with the Ordnance

Department's developmental work on a re-loadable cartridge case in 1879. At

this time, the US government was overly restrictive in its funding of the

military, to the extent that regulations stipulated that only 10 rounds of

rifle ammunition were allowed per man per month for target practice. so, one

of the primary benefits of a re-loadable cartridge case was that it would

provide a plentiful and (most important) cheap source of ammunition to be

used by the troops. The tool set shown

here

is referred to as the Model 1883 set, and was intended for reloading the .45 Colt revolver

cartridge and three different .45 cartridges for the Springfield Trapdoor -

the .45-55 carbine cartridge, and the .45-70 (2.1") and .45-80 (2.4") rifle

cartridges. Similar sets of tools were also made for the .50-70, the 20

gauge 'forager' shotgun shell, and the various 30 caliber rifle cartridges

(.30-40, .30-03, and .30-06). It is estimated that only a few hundred of these

sets of 45 caliber tools were manufactured, and very few are found intact

today due to the heavy use and misuse that they tended to be subjected to.

During the years that they were in use, Ordnance Department

records reveal that large numbers of the individual tools were produced to

replace those that here

is referred to as the Model 1883 set, and was intended for reloading the .45 Colt revolver

cartridge and three different .45 cartridges for the Springfield Trapdoor -

the .45-55 carbine cartridge, and the .45-70 (2.1") and .45-80 (2.4") rifle

cartridges. Similar sets of tools were also made for the .50-70, the 20

gauge 'forager' shotgun shell, and the various 30 caliber rifle cartridges

(.30-40, .30-03, and .30-06). It is estimated that only a few hundred of these

sets of 45 caliber tools were manufactured, and very few are found intact

today due to the heavy use and misuse that they tended to be subjected to.

During the years that they were in use, Ordnance Department

records reveal that large numbers of the individual tools were produced to

replace those that

were damaged or misplaced. As a result, very few of the early sets exist today, and those sets that are found tend to have tools

with a mix of inspector's marks, indicating that some of the tools are

replacements. All the tools in this set except the mallet and the priming

tool are shown in the second picture above. Inspector's marks appear on most

of the steel parts. All but one of those were inspected by Major Ormond Mitchell Lissak,

who used the letters 'O.M.L.' as his inspection mark. Major Lissak is

thought to have inspected most of the Model 1883 tool sets, or he inspected

the majority of the replacement tools manufactured for these sets, as his

initials usually appear on the tools in the sets found today. The third

picture above shows the resizing die and the loading and crimping die for

the carbine, rifle and marksman's rifle (2.4") cartridges. The loading and

crimping were damaged or misplaced. As a result, very few of the early sets exist today, and those sets that are found tend to have tools

with a mix of inspector's marks, indicating that some of the tools are

replacements. All the tools in this set except the mallet and the priming

tool are shown in the second picture above. Inspector's marks appear on most

of the steel parts. All but one of those were inspected by Major Ormond Mitchell Lissak,

who used the letters 'O.M.L.' as his inspection mark. Major Lissak is

thought to have inspected most of the Model 1883 tool sets, or he inspected

the majority of the replacement tools manufactured for these sets, as his

initials usually appear on the tools in the sets found today. The third

picture above shows the resizing die and the loading and crimping die for

the carbine, rifle and marksman's rifle (2.4") cartridges. The loading and

crimping

die

is the one inspected tool in this set that does not bear Major Lissak's

mark. It is marked 'O.E.M.', indicating it was inspected by

Captain Otho Ernest Michaelis. He apparently was a creative sort, as he was issued an 1883

patent on the adjustable powder and shot measure, the silver dipper-looking

object on the upper right side of the picture up above. The fourth picture

above shows the sizing die and the loading and die

is the one inspected tool in this set that does not bear Major Lissak's

mark. It is marked 'O.E.M.', indicating it was inspected by

Captain Otho Ernest Michaelis. He apparently was a creative sort, as he was issued an 1883

patent on the adjustable powder and shot measure, the silver dipper-looking

object on the upper right side of the picture up above. The fourth picture

above shows the sizing die and the loading and

crimping

die for the revolver cartridge. These dies were manufactured at the

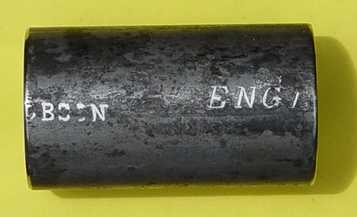

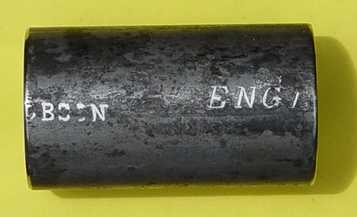

arsenal from round steel rod that was imported from Sheffield, England. The

rod was cut to length, drilled and finished inside and on the ends. Other

than the stamped markings, the sides of the dies were not finished, as is

apparent on the rifle resizing die, shown in this fifth picture, which still

has a portion of the name of the foundry (?BSIN?) that produced the

steel, and the letters 'ENGL' indicating the country of origin (England).

The sixth picture shows the markings on the reloading punches used with the

loading crimping

die for the revolver cartridge. These dies were manufactured at the

arsenal from round steel rod that was imported from Sheffield, England. The

rod was cut to length, drilled and finished inside and on the ends. Other

than the stamped markings, the sides of the dies were not finished, as is

apparent on the rifle resizing die, shown in this fifth picture, which still

has a portion of the name of the foundry (?BSIN?) that produced the

steel, and the letters 'ENGL' indicating the country of origin (England).

The sixth picture shows the markings on the reloading punches used with the

loading

and

crimping dies to seat the bullets to the proper depth. From the left, these

are for the revolver (marked REV), carbine (marked C), and rifle cartridges.

All three have Major Lissak's inspection mark. The punches for the revolver

and carbine show little use, still possessing much of their original

case colors. The last picture shows the six sides of the combination anvil,

a tool which in 1883 replaced the 'safety socket' that is mentioned in the

reloading instructions on most of the old Frankford Arsenal boxes of reloadable ammunition. Each of

the sides serves a specific purpose in the loading process for one or more

of the

different cartridges. and

crimping dies to seat the bullets to the proper depth. From the left, these

are for the revolver (marked REV), carbine (marked C), and rifle cartridges.

All three have Major Lissak's inspection mark. The punches for the revolver

and carbine show little use, still possessing much of their original

case colors. The last picture shows the six sides of the combination anvil,

a tool which in 1883 replaced the 'safety socket' that is mentioned in the

reloading instructions on most of the old Frankford Arsenal boxes of reloadable ammunition. Each of

the sides serves a specific purpose in the loading process for one or more

of the

different cartridges.

.

.

.

.

.

.

.

.

.

.

A tin of Frankford Arsenal primers....

It seems appropriate that I include a tin of the primers that might have

been used with the reloading tools pictured above. This 500 count tin of

primers was made at the Frankford Arsenal in 1901, and is intended for use

with all .45 caliber, .30 caliber gallery, and shotgun black powder

ammunition. The primers fit into holes in round pieces of cardboard, ten of

which are stacked in the tin, with a piece of cloth between each layer. The

patent for this primer was issued on October 14th, 1879 to Jabez H. Gill.

This is the primer that Frankford Arsenal used as they made the change from

the Benet inside-primed cartridge to the

externally primed

cartridge, which was put into production beginning in August of 1882.

Several views of this primer are shown in this picture, including the

disassembled primer cup and anvil. I've also included Gill's

patent drawing and specifications, as taken from the U.S.Patent Office web

page at

http://www.uspto.gov/patft/index.html . externally primed

cartridge, which was put into production beginning in August of 1882.

Several views of this primer are shown in this picture, including the

disassembled primer cup and anvil. I've also included Gill's

patent drawing and specifications, as taken from the U.S.Patent Office web

page at

http://www.uspto.gov/patft/index.html .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

A box of .45-80-500 long range

cartridges......

.

.

.

.

.

.

.

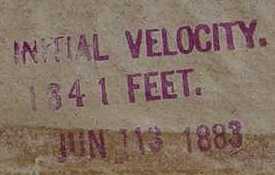

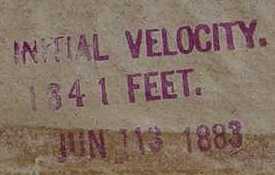

Here's a box of .45-80-500 long range rifle cartridges, made at the

Frankford Arsenal on June 13, 1883. This is the cartridge with the 2.4"

shell that could be reloaded with the tool set shown above; these are

headstamped R 6 F 83. Note the reloading instructions on

the front of the box. This cartridge was  produced

over a five year period, from April of 1880 through April of 1884, for use

with a rifle being experimented with at the Springfield Armory. In addition

to having 10 more grains of powder than the standard .45-70 cartridge, the

long range cartridge had a 500 grain bullet, compared with the standard 405

grain bullet. The results of the tests in 1881 revealed that the cartridge

was more accurate, but that it was the heavier bullet that was responsible

for the accuracy, and not the heavier powder load. As a result, the 500

grain bullet was adopted in January of 1882 as the standard for rifle

cartridges, the 405 grain bullet being retained for use with the carbine. produced

over a five year period, from April of 1880 through April of 1884, for use

with a rifle being experimented with at the Springfield Armory. In addition

to having 10 more grains of powder than the standard .45-70 cartridge, the

long range cartridge had a 500 grain bullet, compared with the standard 405

grain bullet. The results of the tests in 1881 revealed that the cartridge

was more accurate, but that it was the heavier bullet that was responsible

for the accuracy, and not the heavier powder load. As a result, the 500

grain bullet was adopted in January of 1882 as the standard for rifle

cartridges, the 405 grain bullet being retained for use with the carbine.

.

.

|

here

is referred to as the Model 1883 set, and was intended for reloading the .45 Colt revolver

cartridge and three different .45 cartridges for the Springfield Trapdoor -

the .45-55 carbine cartridge, and the .45-70 (2.1") and .45-80 (2.4") rifle

cartridges. Similar sets of tools were also made for the .50-70, the 20

gauge 'forager' shotgun shell, and the various 30 caliber rifle cartridges

(.30-40, .30-03, and .30-06). It is estimated that only a few hundred of these

sets of 45 caliber tools were manufactured, and very few are found intact

today due to the heavy use and misuse that they tended to be subjected to.

During the years that they were in use, Ordnance Department

records reveal that large numbers of the individual tools were produced to

replace those that

here

is referred to as the Model 1883 set, and was intended for reloading the .45 Colt revolver

cartridge and three different .45 cartridges for the Springfield Trapdoor -

the .45-55 carbine cartridge, and the .45-70 (2.1") and .45-80 (2.4") rifle

cartridges. Similar sets of tools were also made for the .50-70, the 20

gauge 'forager' shotgun shell, and the various 30 caliber rifle cartridges

(.30-40, .30-03, and .30-06). It is estimated that only a few hundred of these

sets of 45 caliber tools were manufactured, and very few are found intact

today due to the heavy use and misuse that they tended to be subjected to.

During the years that they were in use, Ordnance Department

records reveal that large numbers of the individual tools were produced to

replace those that

were damaged or misplaced. As a result, very few of the early sets exist today, and those sets that are found tend to have tools

with a mix of inspector's marks, indicating that some of the tools are

replacements. All the tools in this set except the mallet and the priming

tool are shown in the second picture above. Inspector's marks appear on most

of the steel parts. All but one of those were inspected by Major Ormond Mitchell Lissak,

who used the letters 'O.M.L.' as his inspection mark. Major Lissak is

thought to have inspected most of the Model 1883 tool sets, or he inspected

the majority of the replacement tools manufactured for these sets, as his

initials usually appear on the tools in the sets found today. The third

picture above shows the resizing die and the loading and crimping die for

the carbine, rifle and marksman's rifle (2.4") cartridges. The loading and

crimping

were damaged or misplaced. As a result, very few of the early sets exist today, and those sets that are found tend to have tools

with a mix of inspector's marks, indicating that some of the tools are

replacements. All the tools in this set except the mallet and the priming

tool are shown in the second picture above. Inspector's marks appear on most

of the steel parts. All but one of those were inspected by Major Ormond Mitchell Lissak,

who used the letters 'O.M.L.' as his inspection mark. Major Lissak is

thought to have inspected most of the Model 1883 tool sets, or he inspected

the majority of the replacement tools manufactured for these sets, as his

initials usually appear on the tools in the sets found today. The third

picture above shows the resizing die and the loading and crimping die for

the carbine, rifle and marksman's rifle (2.4") cartridges. The loading and

crimping

die

is the one inspected tool in this set that does not bear Major Lissak's

mark. It is marked 'O.E.M.', indicating it was inspected by

Captain Otho Ernest Michaelis. He apparently was a creative sort, as he was issued an 1883

patent on the adjustable powder and shot measure, the silver dipper-looking

object on the upper right side of the picture up above. The fourth picture

above shows the sizing die and the loading and

die

is the one inspected tool in this set that does not bear Major Lissak's

mark. It is marked 'O.E.M.', indicating it was inspected by

Captain Otho Ernest Michaelis. He apparently was a creative sort, as he was issued an 1883

patent on the adjustable powder and shot measure, the silver dipper-looking

object on the upper right side of the picture up above. The fourth picture

above shows the sizing die and the loading and

crimping

die for the revolver cartridge. These dies were manufactured at the

arsenal from round steel rod that was imported from Sheffield, England. The

rod was cut to length, drilled and finished inside and on the ends. Other

than the stamped markings, the sides of the dies were not finished, as is

apparent on the rifle resizing die, shown in this fifth picture, which still

has a portion of the name of the foundry (?BSIN?) that produced the

steel, and the letters 'ENGL' indicating the country of origin (England).

The sixth picture shows the markings on the reloading punches used with the

loading

crimping

die for the revolver cartridge. These dies were manufactured at the

arsenal from round steel rod that was imported from Sheffield, England. The

rod was cut to length, drilled and finished inside and on the ends. Other

than the stamped markings, the sides of the dies were not finished, as is

apparent on the rifle resizing die, shown in this fifth picture, which still

has a portion of the name of the foundry (?BSIN?) that produced the

steel, and the letters 'ENGL' indicating the country of origin (England).

The sixth picture shows the markings on the reloading punches used with the

loading

and

crimping dies to seat the bullets to the proper depth. From the left, these

are for the revolver (marked REV), carbine (marked C), and rifle cartridges.

All three have Major Lissak's inspection mark. The punches for the revolver

and carbine show little use, still possessing much of their original

case colors. The last picture shows the six sides of the combination anvil,

a tool which in 1883 replaced the 'safety socket' that is mentioned in the

reloading instructions on most of the old Frankford Arsenal boxes of reloadable ammunition. Each of

the sides serves a specific purpose in the loading process for one or more

of the

different cartridges.

and

crimping dies to seat the bullets to the proper depth. From the left, these

are for the revolver (marked REV), carbine (marked C), and rifle cartridges.

All three have Major Lissak's inspection mark. The punches for the revolver

and carbine show little use, still possessing much of their original

case colors. The last picture shows the six sides of the combination anvil,

a tool which in 1883 replaced the 'safety socket' that is mentioned in the

reloading instructions on most of the old Frankford Arsenal boxes of reloadable ammunition. Each of

the sides serves a specific purpose in the loading process for one or more

of the

different cartridges.

externally primed

cartridge, which was put into production beginning in August of 1882.

Several views of this primer are shown in this picture, including the

disassembled primer cup and anvil. I've also included Gill's

patent drawing and specifications, as taken from the U.S.Patent Office web

page at

externally primed

cartridge, which was put into production beginning in August of 1882.

Several views of this primer are shown in this picture, including the

disassembled primer cup and anvil. I've also included Gill's

patent drawing and specifications, as taken from the U.S.Patent Office web

page at

produced

over a five year period, from April of 1880 through April of 1884, for use

with a rifle being experimented with at the Springfield Armory. In addition

to having 10 more grains of powder than the standard .45-70 cartridge, the

long range cartridge had a 500 grain bullet, compared with the standard 405

grain bullet. The results of the tests in 1881 revealed that the cartridge

was more accurate, but that it was the heavier bullet that was responsible

for the accuracy, and not the heavier powder load. As a result, the 500

grain bullet was adopted in January of 1882 as the standard for rifle

cartridges, the 405 grain bullet being retained for use with the carbine.

produced

over a five year period, from April of 1880 through April of 1884, for use

with a rifle being experimented with at the Springfield Armory. In addition

to having 10 more grains of powder than the standard .45-70 cartridge, the

long range cartridge had a 500 grain bullet, compared with the standard 405

grain bullet. The results of the tests in 1881 revealed that the cartridge

was more accurate, but that it was the heavier bullet that was responsible

for the accuracy, and not the heavier powder load. As a result, the 500

grain bullet was adopted in January of 1882 as the standard for rifle

cartridges, the 405 grain bullet being retained for use with the carbine.