| Contents

Home

General

Info

Ordering

Info

Cartridge

Lists

Patent & Miscellaneous

Rim Fire

Center Fire Pistol

Center Fire Rifle

Metric Rimfire,

Pistol&Rifle

British Pistol and Rifle

Shotgun Shells

Cartridge Boxes &

Related

Posters

This Month's Picture Page

Index to

Picture Pages

Prior Picture Pages:

*

September 2003

*

October 2003

*

November 2003

*

December 2003

*

January 2004

*

February 2004

*

March 2004

*

April 2004

*

May 2004

*

June 2004

*

July 2004

*

August 2004

*

September 2004

*

October 2004

*

November 2004

*

December

2004

*

January 2005

*

February

2005

*

March

2005

*

April

2005

*

May 2005

* June 2005

* July 2005

*

August 2005

*

September

2005

*

October 2005

*

November 2005

*

December 2005

*

January 2006

*

February 2006

*

March 2006

*

April 2006

*May 2006

*June 2006

*July 2006

*August

2006

*September

2006

*October

2006

*November

2006

*December

2006

*January

2007

*February

2007

*March

2007

*April

2007

*May

2007

*June

2007

*July

2007

*August

2007

*September

2007

*October

2007

*November

2007

*December

2007

*January

2008

*February

2008

*March

2008

*April

2008

*May

2008

*June

2008

*July

2008

*August

2008

*September

2008

*October

2008

*November

2008

*December

2008

*January

2009

*February

2009

*March

2009

*April

2009

*May

2009

*June

2009

*July

2009

*August

2009

*September

2009

*October

2009

*November

2009

*December

2009

*January

2010

*February

2010

*March

2010

*April

2010

*May

2010

*June

2010

*July

2010

*August

2010

*September

2010

*October

2010

*November

2010

*December

2010

*January

2011

*February

2011

*March

2011

There are no picture pages

for April thru June 2011

*July

2011

*August

2011

*September

2011

*October

2011

*November

2011

*December

2011

Links to Other Sites

Cartridge Collectors Organizations:

IAA

ECRA

SAAACA

Auctions:

Auction

Arms

E-Bay

Ward's Collectibles

Sold USA

Books:

Armory

Publications

WCF Publications

Other Collector's Sites:

Curtis Steinhauer

|

Home of the Old Ammo Guy's Virtual

Cartridge Trading Table

Picture Page

January 2012

Ballistic Research Industries sabot bullet cartridges......

A couple of weeks ago, a

gentleman was kind enough to send me a group of cartridges and several

cartridge boxes that he had

accumulated while serving as the production manager of Ballistic Research

Industries (BRI), a small California ammunition company that was involved in

developing sabot bullet cartridges. BRI was eventually bought out by

Winchester Corp.

I include here his remarks

regarding the company and its products, his descriptions of the items he

sent, and a Guns and Ammo article that discusses the company and its

products which he found on the internet.

Without bravado, I feel we pioneered a new era of shotgun slug hunting. With

a scoped rifled shotgun barrel, 3" groups of 5 were the norm at 125

yards. A regular iron sight smooth bore in our guns yielded 3" groups at 50

- 75 yards. Much depended on the shooter, as always; on some days I may as

well have thrown rocks. I will give a brief background of BRI.

I was a local ammunition reloader

commercially in Santa Cruz, California in the late 1970's. I was contacted

by a San Jose attorney to inquire about partnering with him to develop the

BRI sabot round, which he had acquired from the original inventors, and

which still needed improvement. Later, I became a partner with him and

another person in developing and marketing this product. It was a trying

process to fine tune it to achieve the needed results. Just changing the dye

color of the sabot produced a variance in accuracy. We had many colors;

neutral worked best in 12 gauge, but sucked in 20 gauge as I discovered

later. A year later we were ready with the final product, later expanding to

20 gauge, also. We tested many cases, settling on Fiocchi, who also offered

to design a much needed upgraded loader. Fiocchi engineers designed our

loading machine for heavy production around their shell cases, which we

purchased from them with our logo and headstamp. Our operator and I went to

Italy for 3 weeks of training on the machine when it was ready. They were

wonderful folks at the plant. We were treated to a very in-depth tour of the

munitions plant, as well as various cultural outings after hours. If you

don't drink wine, you might as well jump under a bus.

During production years I focused

on quality control and testing at the range. Firing hundreds of rounds a

week which was not always a pleasure, especially the magnums, continually

testing various guns, components, and powders. Experimenting was enjoyable

generally though. We had many letters from hunters who recounted

satisfactory hunts of game for which the round was not intended nor

recommended. Grizzlies, African game, and some I would not want to hunt with

anything. This was a deer slug, but the penetration was indeed impressive.

The mainstay was the 12 gauge round but the 20 gauge was a close second,

very accurate and a light recoil. The 16 ga. was almost impossible to make

conform to acceptable standards for accuracy. Many times I wanted to trash

it but we had to get it to work. After getting a new component for wad

composition, it was on track and acceptable. Subsequently, Winchester bought

the corporation and I went on to other things.

I have not followed any shotgun

slug development since those days, shotgun ammunition just has never held my

interest at all. I have not saved many materials, regrettably, just a few

items:

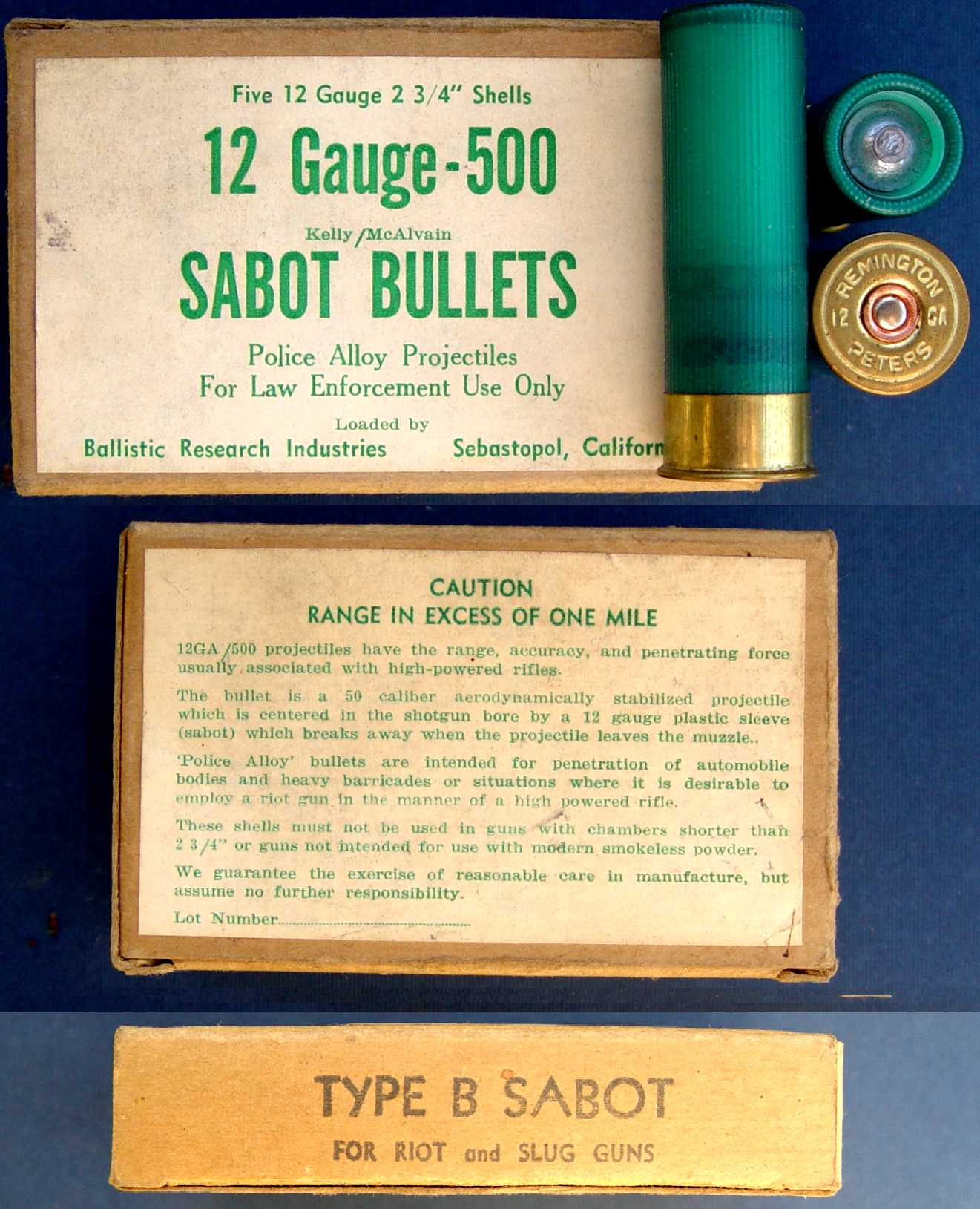

Photo #1 (with his descriptions):

(with his descriptions):

1. On the left, a red sabot armor piercing projectile developed for

police. At 100 yards this would penetrate a 1/4 inch steel plate . This one

is missing the base plug. The plug lightened the tail for better trajectory

on any slug,

2. In the middle, the white sabot slug is the standard configuration

for a regular deer slug, also missing the plug. This slug is not as shiny

and bright as our standard slug was; this is actually a reject.

3. On the right is a Gualandi slug designed by an engineer at the

Fiocchi Ammunition plant in Italy, as I was informed. This was a very

accurate round up to125 yards . We loaded this also and marketed it as the12,

20 and 16 gauge Gualandi.

.

.

Photo # 2 : :

1. Uncrimped 12 gauge AP - The APs were only available in 3 inch magnum.

2. Uncrimped 12 gauge BRI

Gualandi cartridge.

3. Crimped 12 gauge Gualandi loaded at the Fiocchi plant

4. Crimped 12 gauge BRI

deer sabot slug, 3 inch magnum.

5. Yellow hulled 20 gauge BRI 3 inch magnum sabot slug

6. 410 gauge - This is a round ball on a piston wad. We did not have a real

market in the sabot design, just was not practical, but so many wholesalers

wanted " something" in 410 so we selected this design.

Photo # 3 : :

1. An empty blue hulled 16 gauge case. This was never very popular, but

again our dealers pressed for it so we made it.

2. A green tubular slug in a very unusual design. I got a few boxes of these

in Italy, very accurate at 25 feet (lol) with nice light recoil.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

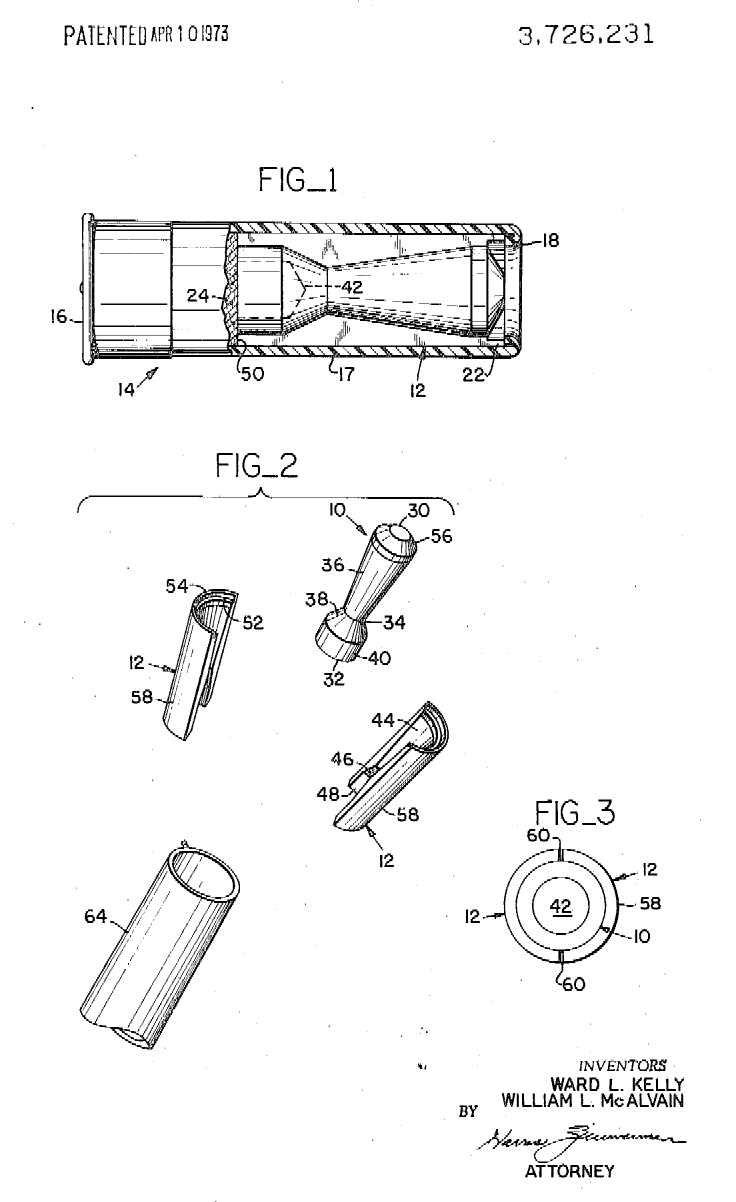

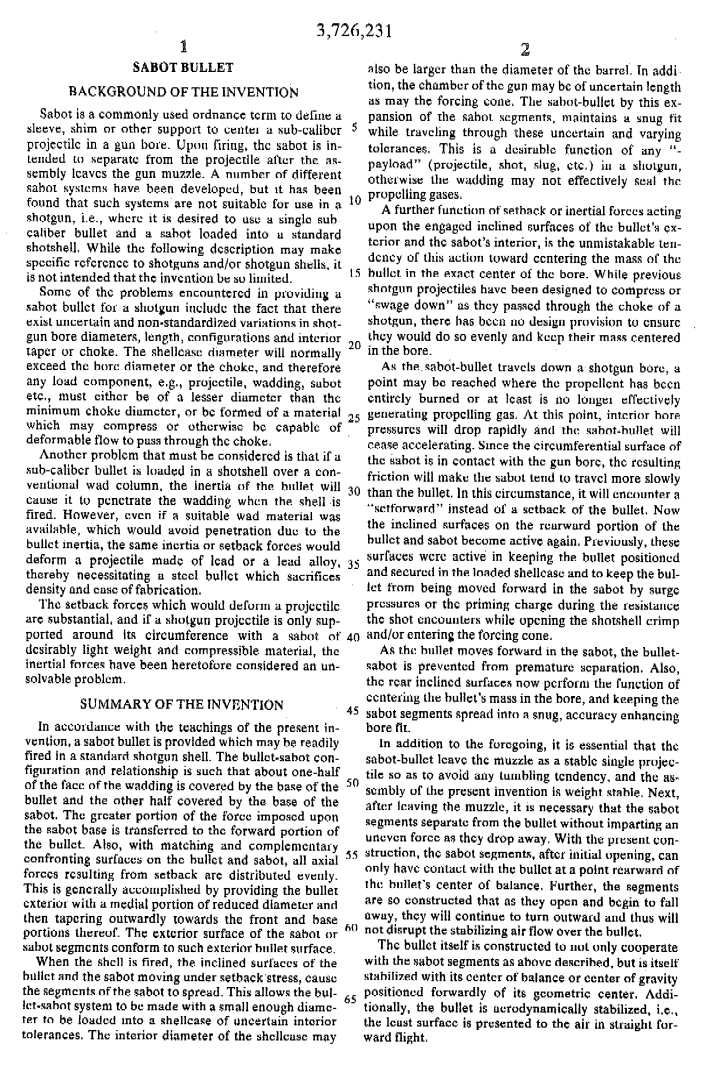

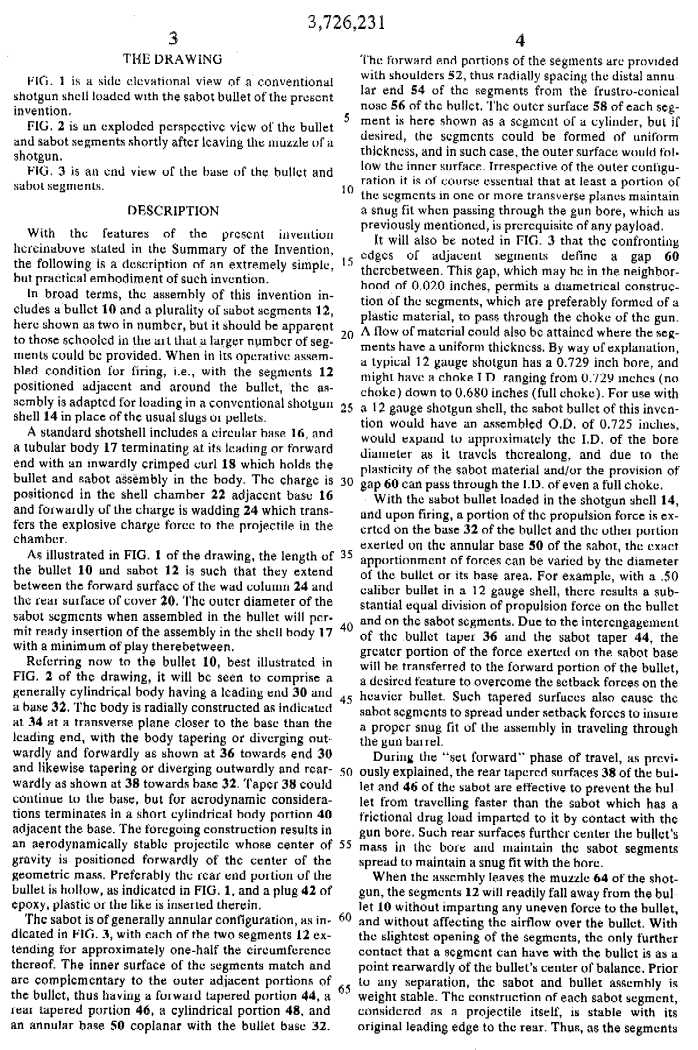

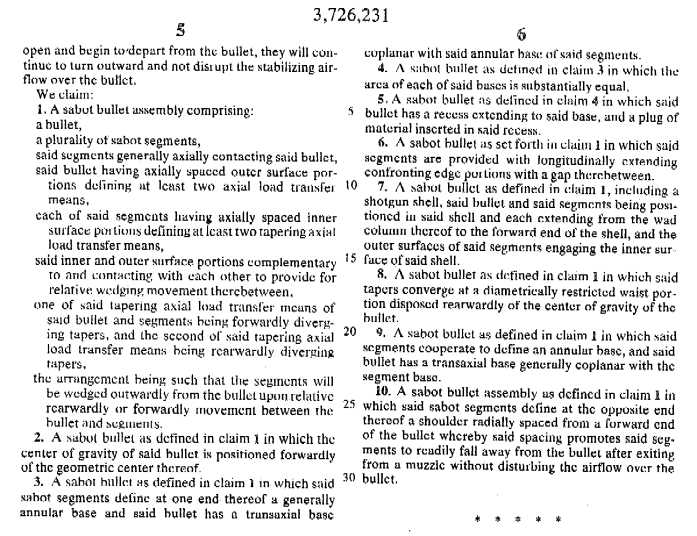

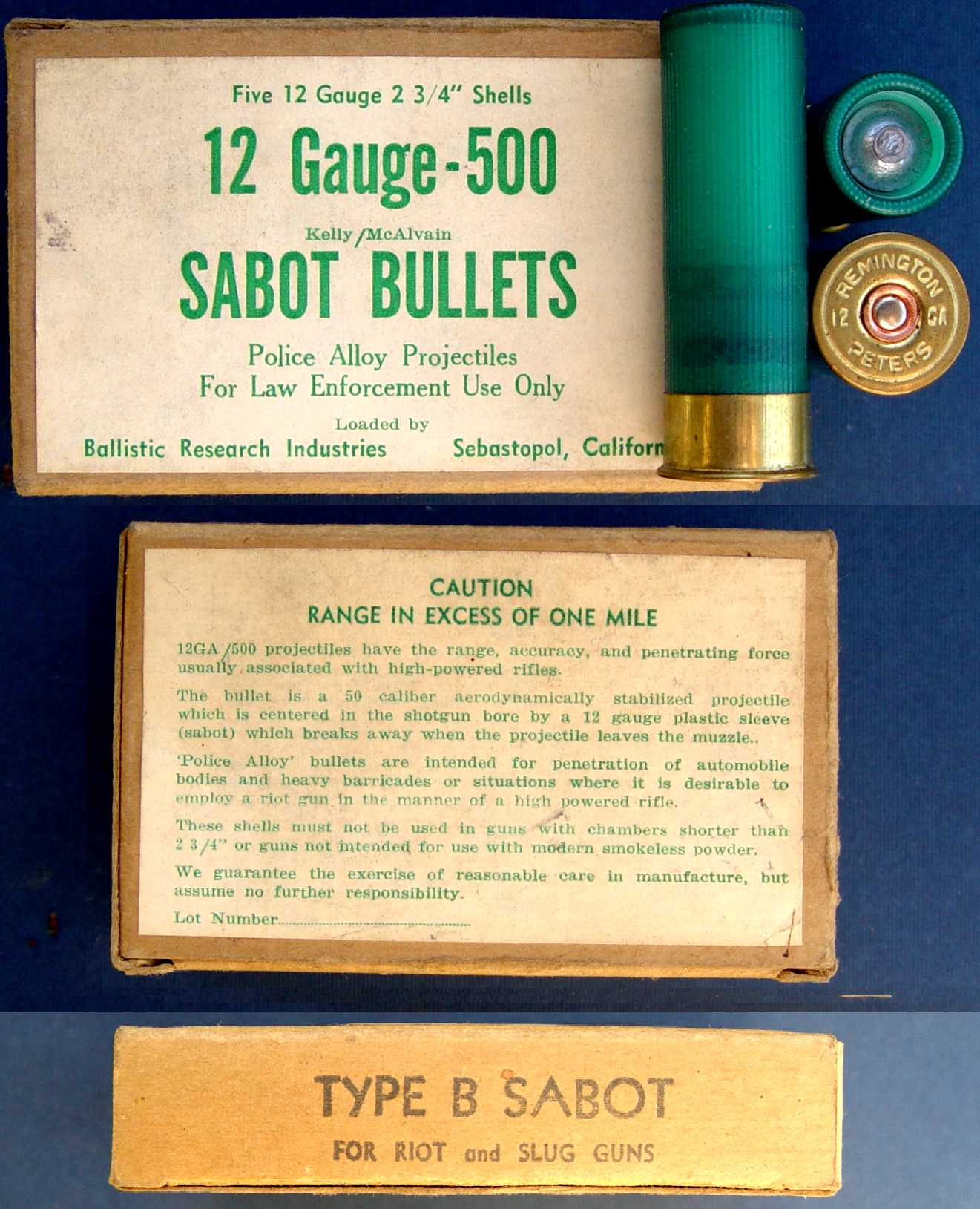

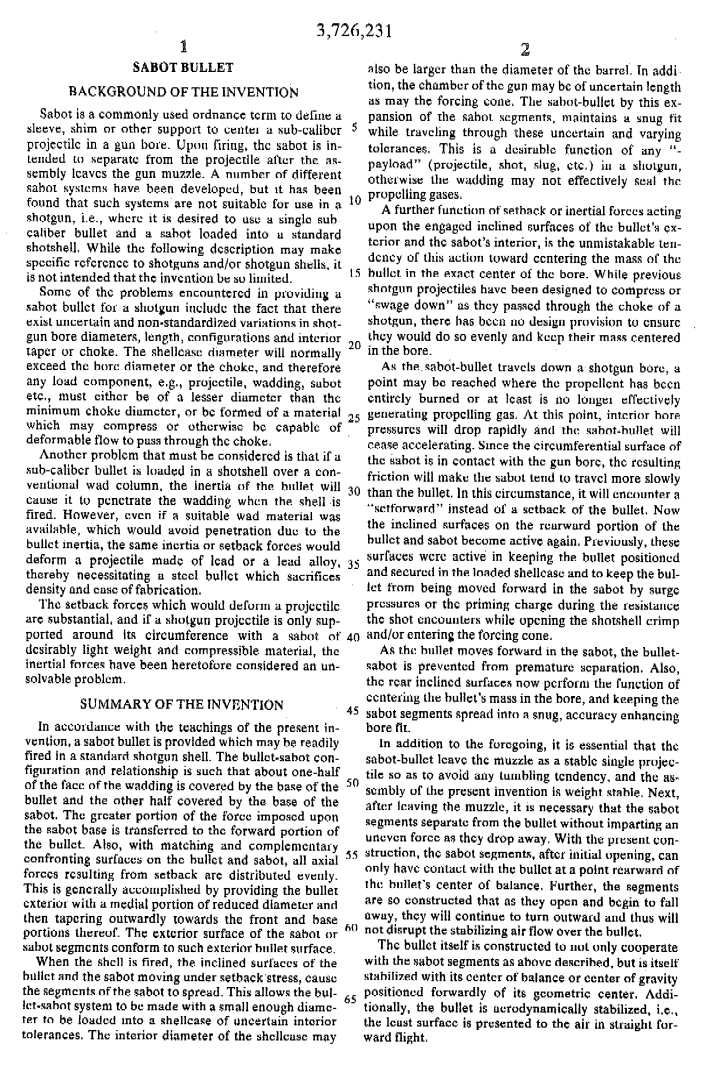

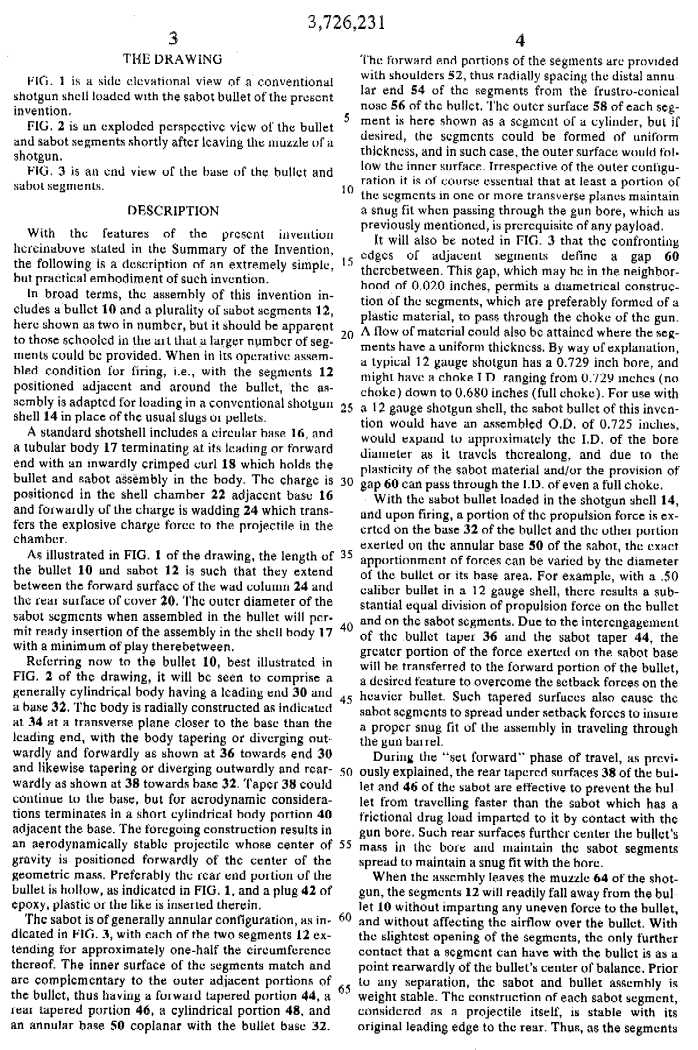

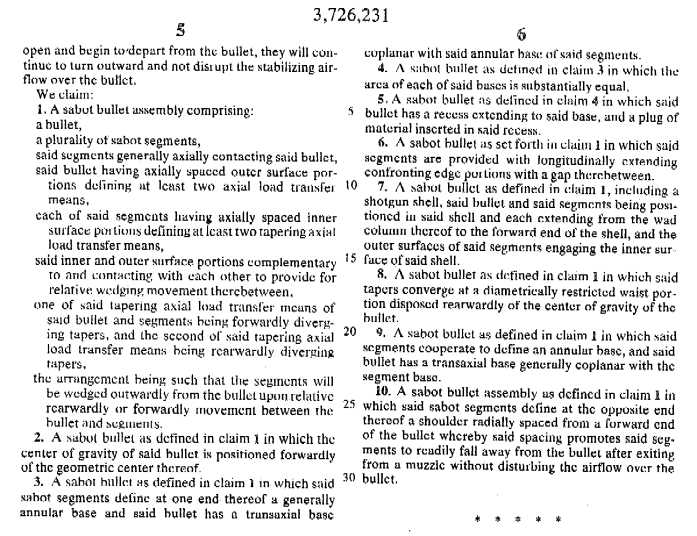

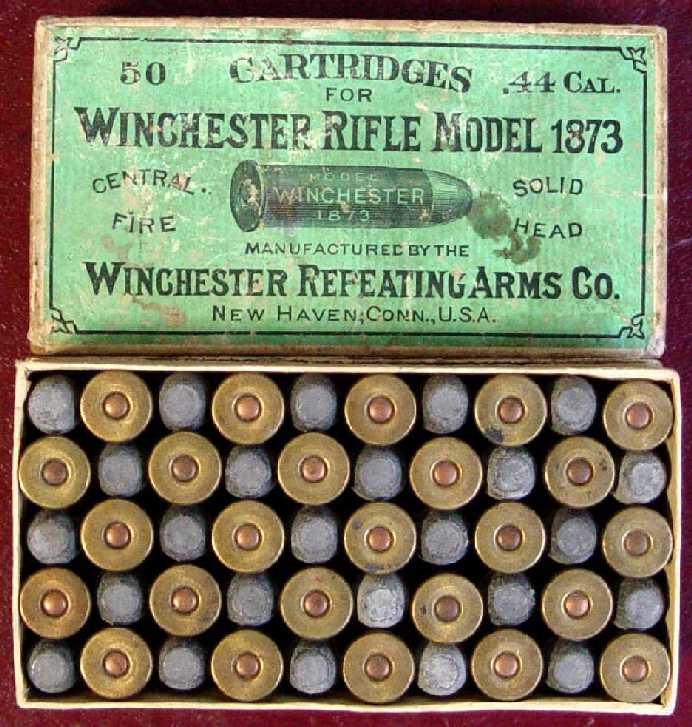

The two BRI 12 gauge (.500) sabot

bullet boxes pictured below are early examples that were

obtained by the gentleman who sent me the cartridges from the original inventors of the sabot slug cartridge,

Ward L. Kelly and William L. McAlvain. Kelly and McAlvain filed the patent

application for their sabot bullet on May 10th, 1970, receiving their patent

on April 10th, 1973. I have included the patent drawing and specifications

below, also. The labeling on these

boxes suggest that they were produced sometime prior to 1963, based on the lack of a 'keep out

of reach of children warning' and the company address with no zip code.. The US Government mandated the

use of this warning on all ammunition sold in this country beginning in

1962. In addition, there is no zip code in the company address; Zip codes

were required by the US Postal Service beginning in 1963. This may indicate

that Kelly and AcAlvain began work on their design at least 8 years prior to

applying for their patent. Note that the labeling on both boxes fails to

include a patent number or any indication that a patent had been applied

for. The shells in both boxes are headstamped REMINGTON PETERS 12 GA.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

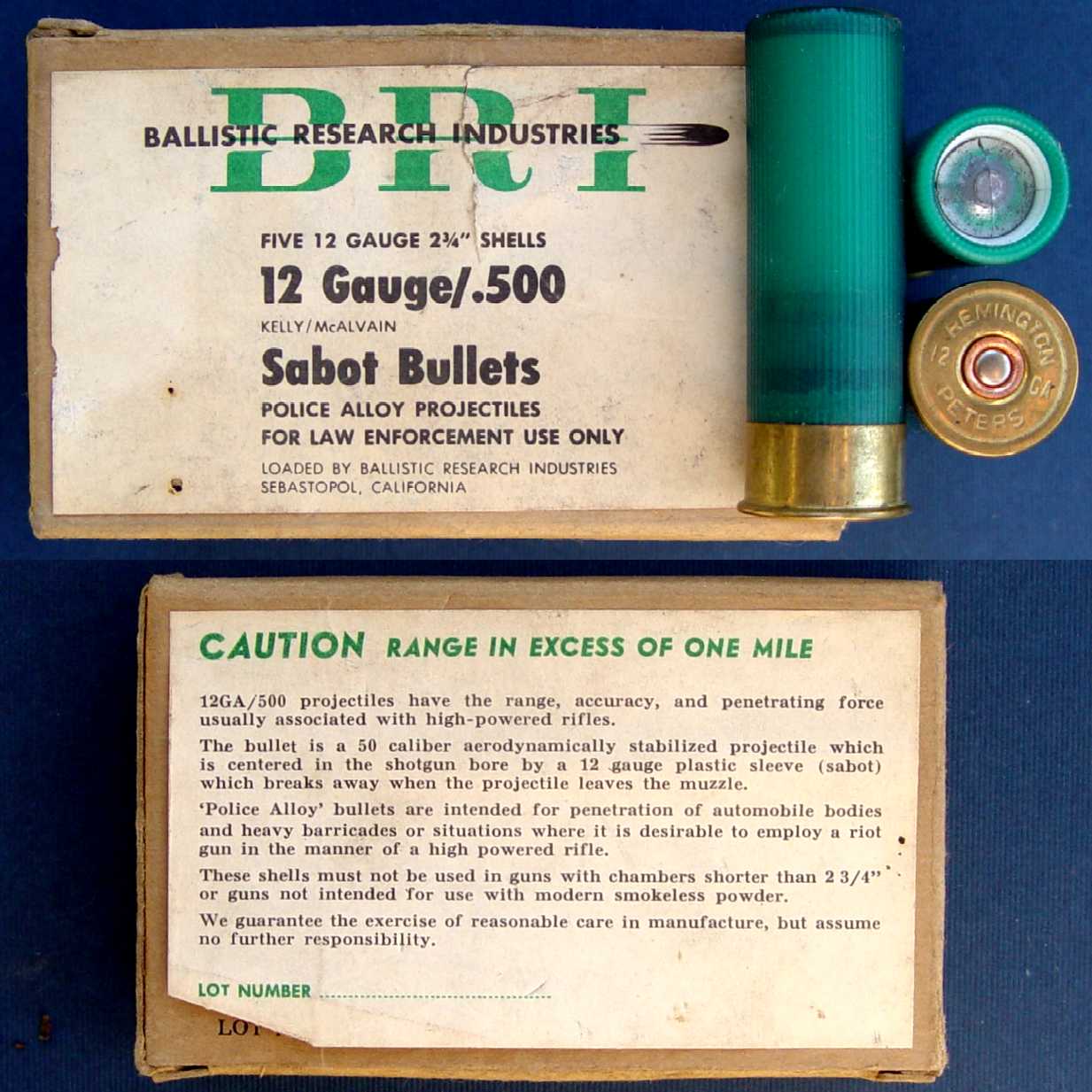

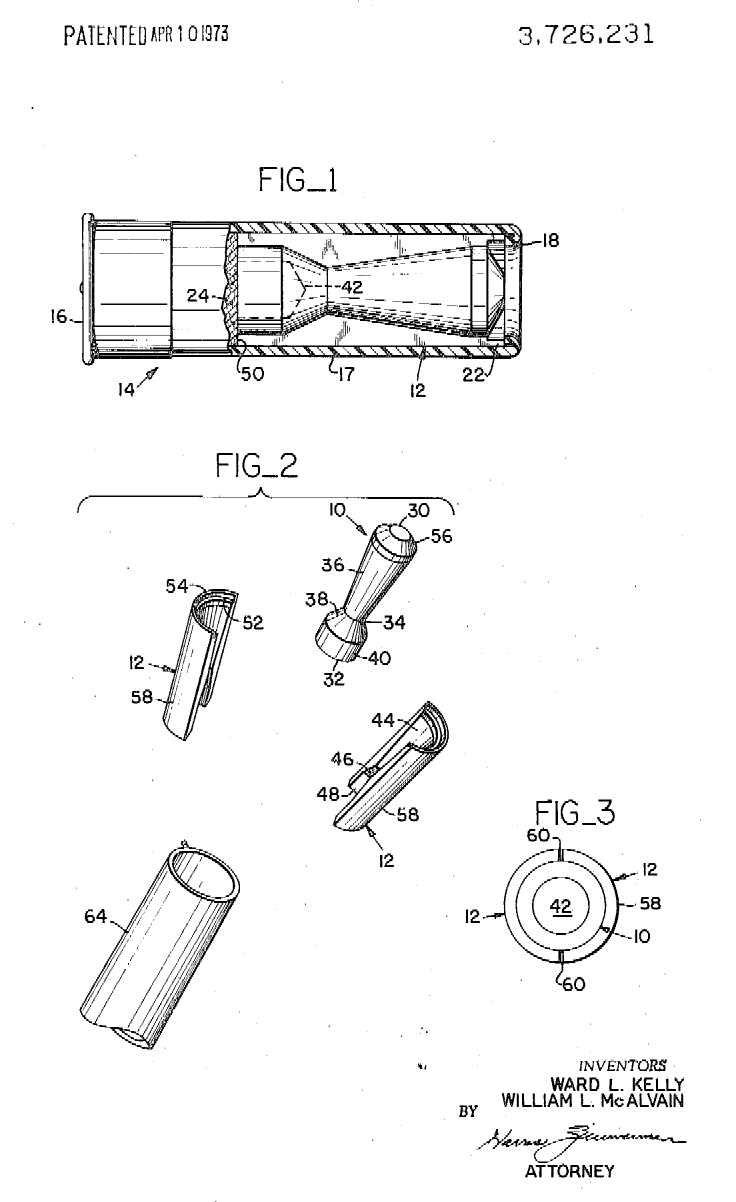

The following is the 1984 Guns

and Ammo article:

BRI 12 gauge .500 sabot bullets.

Ballistic Research Industries is now producing a 440-grain .50 caliber

bullet that is loaded into a shotgun shell. Made in 12 gauge only, the BRI

12 Gauge/.500 has many advantages to offer over an ordinary shotgun slug .

The BRI projectile is better described as a bullet than a slug, since it

more nearly resembles a bullet in both design and performance. The BRI

bullet is encased in a two-piece plastic sleeve (sabot) that separates and

falls away after firing, allowing the bullet to continue down range on its

own. The sabot expands slightly under the force of firing, sealing the bore

and centering the bullet precisely in the barrel. Bullet shape is critical,

since it does not rotate, but is stabilized aerodynamically in flight.

Wasp-waisted in shape, BRI bullets utilize air flow over their rear sections

to achieve flight stability.

BRI bullets have over twice the sectional density of a typical shotgun slug.

Sectional density of the BRI is .251, versus about .107 for a common slug.

What this means is that the BRI will retain its velocity longer, and have

more energy remaining at the target. In fact, at all ranges from zero to 300

yards, BRI bullets deliver more energy than a .45-70, .44 Remington Magnum,

.300 Savage, .30 Remington or .30-30 Winchester--to name a few. A hard lead

alloy is used for making BRI bullets that assures adequate penetration. The

flattened conical tip of BRI bullets imparts maximum shock, yet contributes

to good overall aerodynamic performance.

Accuracy is far superior to the typical rifled slug. One-inch groups were

the norm at 50 yards from our Remington Model 1100 Slug Barrel Many hunting

rifles could do no better.

BRI claims 1,500 feet per second (fps) for their 12 Gauge/.500 bullet, so we

decided to check this out on our own custom Chronograph Model 900. We found,

however, that it was necessary to move the chronograph screens down range

about 25 feet to keep the departing sabots away from the screens' sensitive

areas. If the chrono intercepts a sabot, a false reading is assured. An

instrumental velocity average of 1,228 fps was recorded. For comparison, a

Federal slug was clocked at 1,378 fps, while a Remington stepped out at

1,420 fps. BRI makes a hotter load, for police use only, that registered

1,313 fps. When corrected for distance from the muzzle, chronographed

results will not quite yield a muzzle velocity of 1,500 fps for the BRI

bullet, but it is not too far off the mark.

Components (bullets, sabots and wads) are available for the handloader, so

we just had to load up a few rounds to see how they worked. Since full

investigation of pressures developed in the loads that were used has not

been carried out, the author is reluctant to make specific recommendations

of powder charges for BRI projectiles. We did, however, achieve velocities

greater than those of loads without obvious signs of excess pressure.

An experienced reloader should have no difficulty loading BRI components.

Loading is quite simple. A cardboard wad and a plastic gas-seal wad are used

between powder and sabot. The loaded column is held in place by a roll

crimp which we applied with a Lyman crimping tool .

BRI 12 Gauge/.500 shells should be fired only from barrels with choked

cylinder or improved cylinder, according to the manufacturer. Firing in a

full choked barrel is definitely not recommended.

Loaded shells and components are available from Ballistic Research

Industries, Dept. GA, 6000B Soquel Ave.,Santa Cruz CA 95062.

COPYRIGHT 1984 InterMedia Outdoors, Inc.

Copyright 1984 Gale, Cengage Learning. All rights reserved.

|